Market Policies for Integrated Circuit Welding

I. Introduction

Integrated Circuit (IC) welding is a critical process in the electronics manufacturing industry, enabling the reliable connection of semiconductor devices to substrates. As technology advances and the demand for smaller, more efficient electronic devices grows, the importance of IC welding becomes increasingly pronounced. This blog post will explore the market policies surrounding IC welding, examining the processes involved, market dynamics, regulatory frameworks, and future trends.

II. Understanding Integrated Circuit Welding

A. Explanation of the IC Welding Process

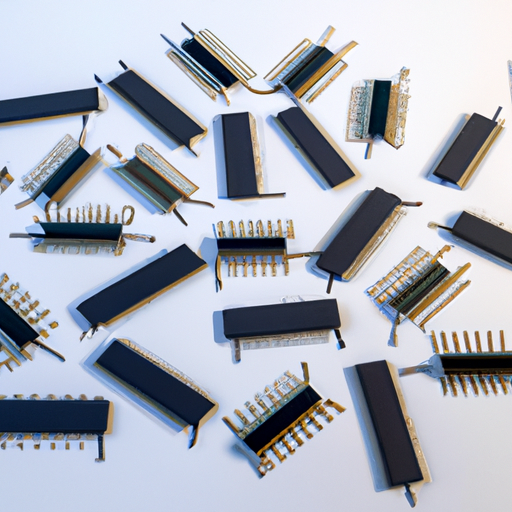

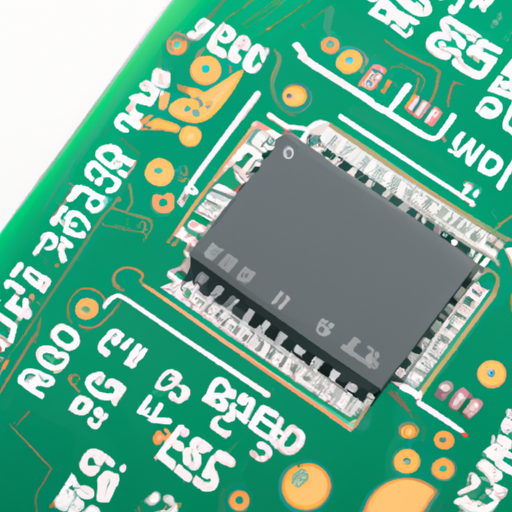

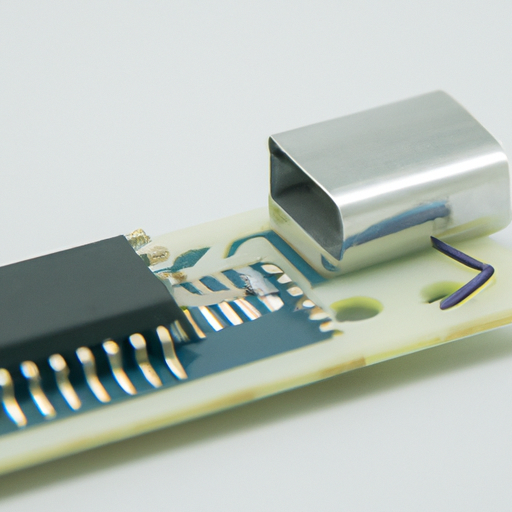

IC welding refers to the methods used to connect integrated circuits to other components, ensuring electrical and mechanical integrity. The two primary techniques are wire bonding and flip chip bonding.

1. **Wire Bonding**: This technique involves using fine wires to connect the IC's pads to the package or substrate. It is widely used due to its cost-effectiveness and reliability.

2. **Flip Chip Bonding**: In this method, the IC is flipped upside down, and its pads are directly attached to the substrate using solder bumps. This technique allows for higher density and better performance, making it suitable for advanced applications.

B. Applications of IC Welding

IC welding plays a vital role in various industries:

1. **Consumer Electronics**: From smartphones to laptops, IC welding is essential for ensuring the functionality of electronic devices.

2. **Automotive Industry**: Modern vehicles rely heavily on electronics for safety, navigation, and entertainment systems, making IC welding crucial for automotive applications.

3. **Telecommunications**: The demand for faster and more reliable communication networks drives the need for advanced IC welding techniques.

4. **Medical Devices**: In the medical field, precision and reliability are paramount, making IC welding a critical process in the manufacturing of medical devices.

III. Market Dynamics

A. Global Market Overview

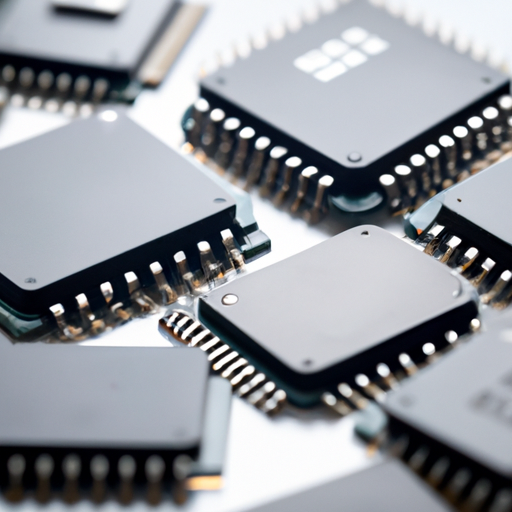

The global IC welding market has experienced significant growth, driven by technological advancements and increasing demand for miniaturized electronic components. Key players in the market include major semiconductor manufacturers and specialized equipment suppliers.

B. Demand Drivers

Several factors are driving the demand for IC welding:

1. **Technological Advancements**: Innovations in semiconductor technology necessitate advanced welding techniques to ensure performance and reliability.

2. **Increasing Demand for Miniaturization**: As devices become smaller, the need for efficient and compact IC welding methods grows.

3. **Growth of the Internet of Things (IoT)**: The proliferation of IoT devices has created a surge in demand for integrated circuits, further fueling the need for effective welding solutions.

C. Challenges in the Market

Despite the growth potential, the IC welding market faces several challenges:

1. **Supply Chain Disruptions**: Global events, such as the COVID-19 pandemic, have highlighted vulnerabilities in supply chains, affecting the availability of materials and components.

2. **Environmental Regulations**: Increasing scrutiny on environmental impacts requires manufacturers to adopt sustainable practices, which can complicate production processes.

3. **Competition from Alternative Technologies**: Emerging technologies, such as advanced packaging solutions, pose a threat to traditional IC welding methods.

IV. Regulatory Framework

A. Overview of Regulatory Bodies

The IC welding industry is governed by various regulatory bodies that establish standards and guidelines to ensure safety and quality. Key organizations include:

1. **International Standards Organizations (ISO)**: These organizations develop global standards that promote quality and safety in manufacturing processes.

2. **National Regulatory Agencies**: Agencies such as the Federal Communications Commission (FCC) and Conformité Européenne (CE) set regulations that manufacturers must comply with to ensure product safety and performance.

B. Compliance Requirements

Manufacturers must adhere to several compliance requirements, including:

1. **Safety Standards**: Ensuring that products meet safety regulations is crucial for protecting consumers and maintaining market access.

2. **Environmental Regulations**: Compliance with environmental laws is increasingly important, requiring manufacturers to adopt sustainable practices.

3. **Quality Assurance Protocols**: Implementing rigorous quality control measures is essential for maintaining product reliability and customer satisfaction.

V. Market Policies and Strategies

A. Government Policies

Government policies play a significant role in shaping the IC welding market:

1. **Incentives for Research and Development**: Many governments offer financial incentives to encourage innovation in semiconductor technologies, including IC welding.

2. **Trade Policies Affecting IC Welding**: Tariffs and trade agreements can impact the cost and availability of materials and equipment used in IC welding.

3. **Support for Domestic Manufacturing**: Policies aimed at bolstering domestic manufacturing can enhance the competitiveness of local IC welding companies.

B. Industry Standards and Best Practices

Adopting industry standards and best practices is crucial for ensuring quality and reliability in IC welding:

1. **Adoption of Industry Standards**: Organizations such as IPC and JEDEC provide guidelines that help manufacturers maintain high-quality production processes.

2. **Best Practices for Quality Control**: Implementing best practices in quality control can minimize defects and enhance product reliability.

C. Intellectual Property Considerations

Intellectual property (IP) is a critical aspect of the IC welding market:

1. **Patent Regulations**: Protecting innovations through patents is essential for maintaining a competitive edge in the market.

2. **Trade Secrets and Confidentiality**: Companies must safeguard their proprietary processes and technologies to prevent unauthorized use by competitors.

VI. Economic Impact of Market Policies

A. Effects on Innovation and Technology Development

Market policies significantly influence innovation in the IC welding sector. Supportive policies can foster research and development, leading to advancements in welding techniques and materials.

B. Impact on Employment and Workforce Development

The growth of the IC welding market can create job opportunities in manufacturing, engineering, and research. However, it also necessitates workforce development programs to equip workers with the necessary skills.

C. Influence on Global Trade Dynamics

Market policies can affect global trade dynamics, influencing the flow of materials and technologies across borders. Trade agreements and tariffs can either facilitate or hinder international collaboration in the IC welding sector.

VII. Future Trends and Predictions

A. Emerging Technologies in IC Welding

The future of IC welding is likely to be shaped by several emerging technologies:

1. **Automation and Robotics**: The integration of automation in IC welding processes can enhance efficiency and reduce labor costs.

2. **Advanced Materials**: The development of new materials, such as nanomaterials, may lead to improved performance and reliability in IC welding.

B. Anticipated Changes in Market Policies

As the industry evolves, market policies are expected to adapt:

1. **Evolving Regulatory Landscape**: Regulatory bodies may introduce new standards to address emerging technologies and environmental concerns.

2. **Sustainability Initiatives**: Increasing emphasis on sustainability will likely drive policies that promote eco-friendly practices in IC welding.

VIII. Conclusion

In conclusion, the market policies surrounding integrated circuit welding are multifaceted, encompassing regulatory frameworks, industry standards, and government initiatives. As the demand for advanced electronic devices continues to grow, the importance of adapting to these policies becomes paramount for manufacturers. By understanding the dynamics of the IC welding market and embracing innovation, companies can position themselves for success in this rapidly evolving industry.

IX. References

1. Academic Journals

2. Industry Reports

3. Regulatory Documents

This blog post provides a comprehensive overview of the market policies for integrated circuit welding, highlighting the importance of understanding the regulatory landscape and market dynamics to thrive in this critical sector of electronics manufacturing.