Information

dict2_description

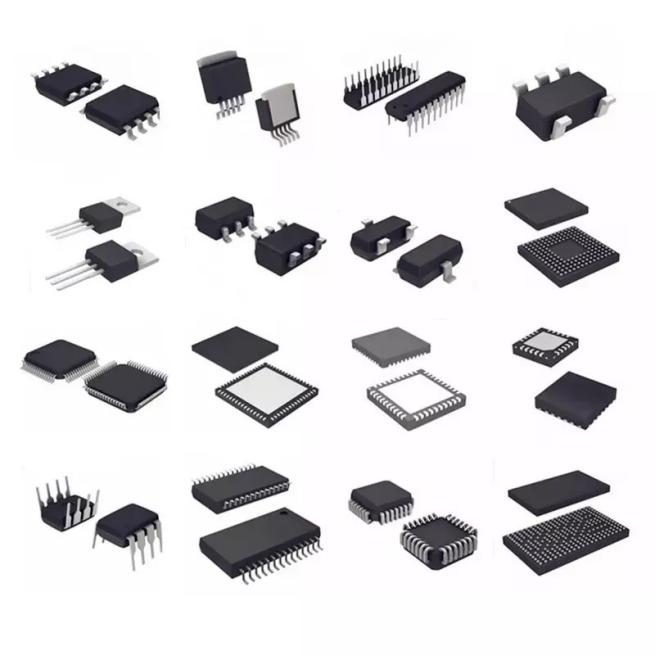

What kind of product is integrated circuit English?

2025-03-09

5

Spot Integrated Circuit Query How should I choose?

2025-03-06

6

dict3_title

dict3_description